The common misconception

First, let’s throw these common misconceptions out of the window — Indian summers and poor thermal management are the reason for fires. That's not true.

The recent fires you see are a result of thermal runaway. Li-ion cells need to hit a few hundred degrees Celsius before having a thermal runaway incident.

Most modern batteries automatically switch off around 45-55°C. And even if these thermal-based safety precautions don't kick in, you won’t see a thermal runaway (fire) because batteries cannot heat themselves up by a few hundred degrees Celsius under normal operations. A battery with a bad thermal design will experience a temperature rise of ~30°C above ambient.

(Sure, climate change is real & summers are getting hotter. But even with an ambient temperature of 50°C, you can’t go beyond ~80°C)

So, why do EV batteries catch fire?

Before we dig deeper, let’s establish 3 metrics that are important for every battery:

Performance

Battery Life

Safety

Hot summers and bad thermal management affect performance & life but don't cause fires. It’s like using your phone on a hot day, after keeping it on the vehicle dashboard — it’s slow, hot, & shortens life. But they don’t affect safety!

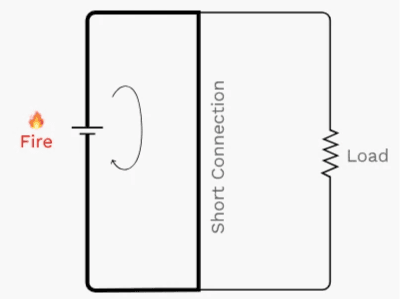

99% of battery fires are due to short circuits leading to uncontrolled current. This is the only scenario in which cells heat themselves up beyond 100°C.

(Kudos to Grin Technologies for capturing this amazing video)

A quick deep dive into cells:

A quick deep dive into cells

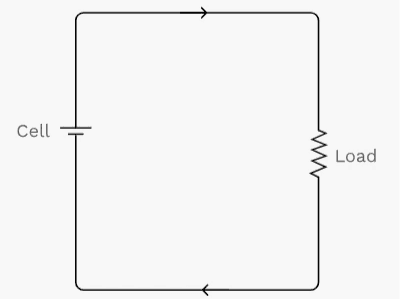

Cells have 2 terminals: an anode (-ve) and a cathode (+ve) which always need to be separated and the space between them is occupied by a separator (aptly named). During discharge, (Fig 1) we connect the anode & cathode up in a controlled fashion through a load (in the case of an EV, it's the motor), and then a controlled current is drawn from the cells.

During a short circuit, there's a short between the battery and load which causes uncontrolled current flow, eventually leading to a B

Controlled current flow

💡 Fun fact

When cells short circuit, they also release flammable gases through a process called cell venting to reduce the probability of thermal runaway (something we’ll talk about later)

Short circuits happen for three reasons:

Poor cell life

Poor battery design

Poor BMS

Poor cell quality

Poor cell quality can cause an “internal short-circuit”. Due to manufacturing irregularities, there can be an issue with how the anode, cathode, and separator are packaged together. An accidental contact internally leads to a short-circuit — this leads to uncontrolled current, eventually causing 🔥

PSA: if you see shrink-wraps like this 👆🏻, excuse yourself politely and run 🏃🏻

On the flip side, you can get the best quality cells and do a great job designing the mechanicals of the battery and still cause fires because of the way you charge them. How? Overcharging!

Poor BMS = Overcharging

When you charge a cell, you take it from a lower voltage to a higher voltage which roughly correlates to the 0% and 100% state of charge (SoC). Different cell chemistries have different voltage thresholds:

LFP goes from 2.8V to 3.6V

NMC goes from 2.8V to 4.2V

Overcharging NMC by even a minuscule 0.05V can drastically promote Lithium dendrite formation.

Overcharging leads to lithium ions crowding around the anode. They eventually deposit themselves on the surface of the anode and create small lithium dendrites (like ice crystals in a cave). As these dendrites grow they move closer to the cathode and eventually connect the two sides leading to an internal short circuit.

Remember our favourite Tetris animation? That's exactly what we meant (albeit, oversimplified)

Overcharging fundamentally happens due to poorly designed BMS hardware (poor sensing & accuracy), lack of BMS intelligence, or a badly written BMS software.

Today, most EVs charge blindly 👀. These modules hold 2-3kWh of energy & are managed by obsolete analog BMSes that are dumb. They are no smarter than an MCB. If a certain cell is acting rogue, current BMSes have no intelligence on how to manage it, leading to an overcharging, dendrite build-up, and eventual thermal runaway.

Overcharging: Up and close

Overcharging leads to dendrite build-up which causes cells to bulge, crush into each other, and in due course cause short-circuiting — eventually leading to a fire. It’s dramatic and you don’t have to imagine it.

And here’s a really cool video we found on Linkedin (Hitoshi Nakamura) showcasing how things actually work on a microscopic level.

Thermostat showing temperature

More overcharge = More bulge = More crush force = Eventual internal short circuit = Fire

All of this gets worst with multiple cells. (And, of course, we had to test that too👇)

We deliberately exploded our battery pack (yes, deliberately) and pushed it to the limit to see when overcharging would lead to a battery fire. The specific objective was to understand propagation (imagine 100s of cells sequentially undergoing thermal runaway). Also, notice negligible propagation.

Trying to purposefully explode our pack takes a lot of effort. We had to switch off all hardware protections on the charger and manually override BMS protections. We normally stop charging at 3.6V, but with this test, we charged it beyond 5V (more overcharging = more bulge) for the battery to actually crush itself enough to catch fire.

FYI: While we passed the global benchmark on battery safety, we were not satisfied with the outcome and since this video, we have iterated thrice to increase cell level spacing.

Solution?

Well, throwing money and buying better cells doesn’t solve battery safety. The problem is collectively shared between.

Mechanical system

Electronics systems

we need accurate BMS sensing and impedance management

Software system

we need deeper intelligence and reliable code that doesn’t crash

And above all, a whole lot of testing.

TEST. TEST. TEST.

That’s why we move fast & break stuff in our labs before taking it out in the field. You need to know your limits to push it (and this was done with all the safety gear, of course)

The overcharging experiment was to test out the use case if a whole bunch of our design & safety precautions including BMS failed for some reason (no, it won’t) but imagine if:

1. A faulty cell passes through and our real-time onboard diagnostics doesn't catch it.

2. Our BMS hardware fails and our baseline safety precautions don't kick in.

3. Our software hangs permanently.

4. Someone charges the vehicle at the exact same time.

(Note: all 4 events must happen together for a thermal runaway)

Yes, we know, that’s more like a one-in-a-billion chance. But even then, certain precautions like planning cell spacing to minimize propagation or planning battery vents to flush gases in the case of cell venting add a whole lot of mileage in making the battery pack extra safe.

Performance and/or Safety

The unfortunate safety incidents recently are a wake-up call to the industry. Many are putting out reassuring messages that their batteries are safe, however, we want you to make an informed decision. While the narrative is changing to how EV companies should prioritise safety over performance, we’re telling you otherwise — you don’t need to trade off performance for safety. We have not.

(The blog has been edited for clarity and ease of readability)